Share to

T650C Universal Iron Bone Wiper

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

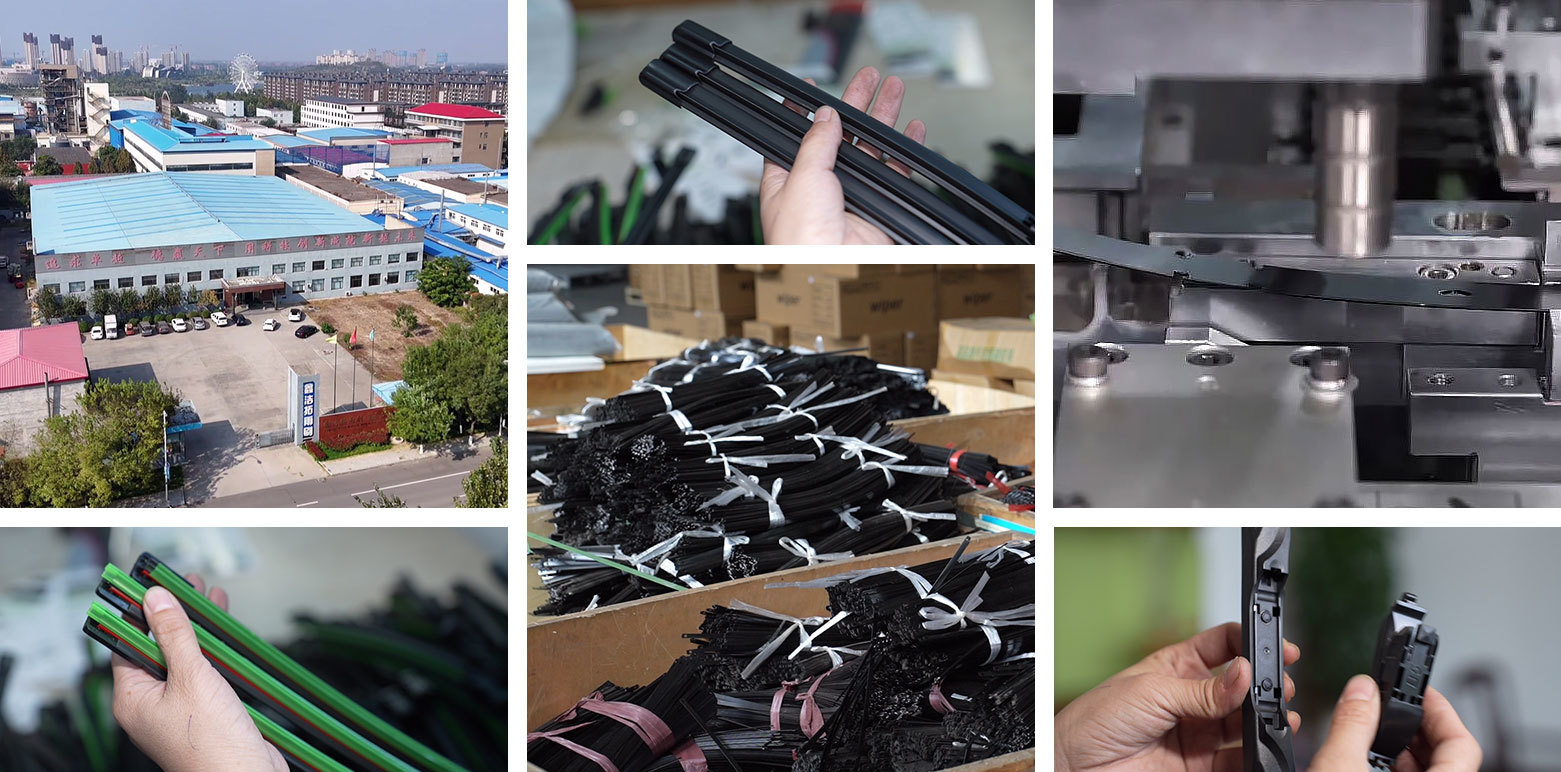

Production Process

Phase 1: Parts Manufacturing and preparation

1. Raw material preparation:

Select the appropriate material. Usually, the skeleton of the CE certification T650C Universal Iron Bone Wiper uses aluminum alloy, steel or plastic, etc., which is selected according to design requirements and cost considerations.2. Metal processing:

For the main part of the iron bone wiper, cut and form the metal material. This may involve the use of CNC machine tools, punch presses and other equipment to ensure that the shape and size of the wiper skeleton meet the design requirements.3. Plastic injection molding (if applicable):

If the wiper skeleton needs to use plastic parts as accessories or connectors, plastic injection molding may be required to ensure part quality and accuracy.Phase 2: Assemble and process Universal Iron Bone Wiper

1. Parts assembly:

Assemble the cut and formed metal parts and plastic parts (if any). This may include assembling the parts of the wiper skeleton together using welding, bolting, or other fixing methods.2. Rubber processing:

Prepare the rubber scraper strip, cut it, and install it according to design requirements. The rubber scraper strip is a key part of the wiper, which is used to remove water from the glass.3. Product debugging and adjustment:

After assembly, preliminary product debugging and adjustment are carried out. Ensure that the wiper can operate normally, the rubber scraper strip is installed correctly, and there is no abnormal noise or poor operation.Phase 3: Quality control and packaging

1. Quality inspection:

Carry out a comprehensive quality inspection on the assembled wipers. Check the appearance quality, functional performance (such as operating stability, wiping effect), durability, and other aspects to ensure that the product meets relevant standards and customer requirements.2. Surface treatment:

The wipers are surface treated, such as galvanizing, painting, etc., to enhance the corrosion resistance and aesthetics of the product.3. Packaging:

Finally, the qualified and CE certification T650C Universal Iron Bone Wiper is packaged. Appropriate packaging materials (such as plastic bags, cartons, etc.) are usually used, and clear product information and barcodes are marked for easy storage, transportation and sales.

Company Advantages

Minman Automotive Parts Co., Ltd. was established in 2002. It is a professional manufacturer and exporter of automotive wipers, specializing in the design, research and development, production, sales, and service of automotive wipers. The company is deeply involved in the wiper industry and has accumulated over 20 years of experience in wiper research and manufacturing. The company adheres to the philosophy of "professionalism, focus, safety, and innovation". Adhering to the spirit of "great country craftsman", adhering to honest management and independent innovation, we have passed the ISO9000 and IATF16949 international quality management system certifications.

T650C Universal Iron Bone Wiper

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!